Hi, new to this forum.

For 20 years I have run fridges in my campers and 4wd with battery and chargers of various types and it all seems pretty easy. In a rash moment I ordered from China 32x 320AH 3.2v batteries to make a big battery for my home. I already have 6.6kw panels and 5Kw inverter so I figured I was part way to going off grid.

I then started researching inverter/chargers, batteries and BMS and all the other bits required and I can see now why people buy a whole system.

Nevertheless I have the batteries arriving in four months and I can’t find much info on DIY systems. Have searched this forum but nothing turns. Has anybody built their own and can give some advice or should I employ an engineer to design it all.

Third option is flog off the batteries when they arrive and go back to the drawing board. The whole reason for doing it myself was to save money and have a challenge.

That is certainly a challenge if you haven’t worked with Lithium batteries before. The key to success here is the BMS system which you can purchase separately but can be very complex. Although, with all the quality lithium batteries now available I’d recommend you sell the cells and purchase something prebuilt with a warranty. It will save you a lot of time and energy (pardon the pun) and more importantly it will be much safer.

Also, you will need a compatible inverter/charger, MPPT, and other equipment. Building a system can be enough of a challenge for most people. Victron is probably the best option.

I’d suggest, with either path you take, definitely go with a 48V battery voltage. It will be much more efficient and less costly.

Sparky. Thanks for your advice. The problem is I can’t afford a prebuilt system, hence the purchase of batteries as a starter. If the batteries are all they are advertised as, I will have 32Kw of battery and with say $5000 for a Victron inverter and a decent BMS I should have most of what is required for a four day reserve of power which should enable us to go off grid, which is the ultimate aim. Our use is 7Khw per day and after looking at solar production for the last 8 years, the longest without much sun has been 3 days until last month when we had four days with only about 6Kwh input. I also have a small generator which we have run on previously when the grid has been down for short periods.

The costs I envisage are way below what a prebuilt one would cost for equivalent storage, unless I am missing something. Even with no warranty on the batteries, I could replace them and still be way in front.

I was planning 16s2p battery for 48volt, Victron Inverter/charger and other stuff not decided on yet. Is there somewhere I can see system designs or get some help with the design. Obviously I will get an electrician in to do the hookup and be sure it is all safe and legal. Should I start with the electrician. I wont be buying anything else until that is all sorted.

Any comments appreciated thanks.

Here’s a simple line diagram for a basic off-grid DC-coupled system… This is a Victron system using pylontech batteries, but the basic layout is the same. The only difference is that you may not need CANbus comms to the battery (depending on what type of BMS you use).

Also, if you haven’t seen this article before, then it could also help with the overall system design and has another line diagram. Solar battery system types - AC Vs DC coupled — Clean Energy Reviews

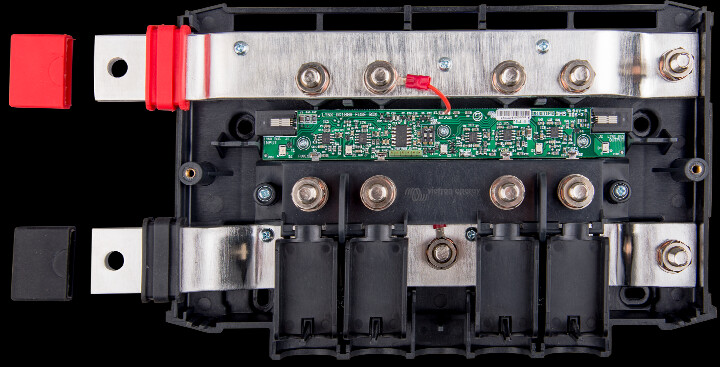

The Victron Lynx distributor would be a great way to connect a DIY battery system safely. It contains 4 fused inputs in a nicely enclosed modular unit.

Hi Jeff;

As a solar off-grid newbie, I’ve been a member of his site for several months. Jason and Sparky are very knowledgeable and have been super helpful.

Been reading your msg thread and I get the impression that you have budget constraints and want more info on building your own 48V (LFP) battery pack(?). If I have misunderstood, then you can ignore the rest of this msg.

Before taking the plunge and installing my own off-grid system, I watched a ton of Youtube videos of other DIY’ers building packs from individual cells. If you are intent on building your own LFP pack and can accept the inherent risks, I found the earlier vids by “Will Prowse” and “David Poz” very informative and instructional.

However to avoid any misrepresentation, in the end, I did opt to buy pre-built 48V 200AH LFP packs, as I had sufficient budget and more importantly was fully preoccupied with building my retirement house.

FYI the packs are from “Blue Carbon Tech”. They were not too expensive (approx USD1500/battery), use BYD LFP cells and have worked without any problems for the past 3+ months. Also bought an ‘all-in-one’ 5KW hybrid charger-inverter from MPP Solar for USD1K. Growatt also offers an almost identical (rip-off?) version. They are really nifty, relatively simple and quick to install. I don’t know how long they will operate but at this low price one can afford to buy a second unit as a stand-by/spare for less than the price of one Victron.

Note that the BCT batteries do NOT have any comms port on their BMS, so cannot be connected to the charger-inverter or monitored remotely. I just check the battery pack voltages a couple of times each day to get a rough indication of their SOC. Not technically elegant nor a state-of-the-art design, but good enough for a retired pensioner like myself with time on his hands. Not sure if this is helpful but throwing it out there in the spirit of sharing with other fellow solar newbies.

Good luck and apologies to Sparky for barging into this thread uninvited…

William

Thank you Svarky for the additional info and thanks Chewface for your input. You have read correctly that my constraint is money, being retired and having time to spare and liking a challenge.

I had looked at the MPP inverters and was impressed but not much feedback available on them. Your idea of having two I like, for much less than the Victron.

The Victron, much as I like the specs and reputed quality was getting a bit expensive by the time I added charger, and other bits for monitoring.

It seems to me that one of the most important things is the BMS and two in my case with 16s2p batteries, with the ability to talk to the charger and inverter. Any suggestions on that front? Do two BMSs talk to each other as well? Should I instead go 2p16s and one BMS? I know two would be better so that’s every battery is protected separately but how do two talk to the charger?

Thanks for the feedback.

Jeff

Don’t try to do it by yourself it might be risky, but we want you can use the below process,

create your own lithium battery system, there are a few things that you will need to do. First, you will need some lithium-ion batteries (these can be bought online or at most hardware stores). Second, you will need an Arduino board (or another microcontroller), which can be used for programming the batteries and controlling their functions. Third, you will need a power supply unit that is capable of supplying voltage and current levels appropriate for the lithium ion battery cells. Fourth, you will need some sensors and actuators to monitor conditions such as temperature and charge level of the cells. Fifth, last but not least,you’ll want software on your computer in order to program all these components using Arduino code or another suitable programming language.

Thanks for the replies but I am back to square one as the batteries never arrived and I got a refund from AliExpress.

I am now looking at a small (5kwh) battery and inverter/charger as I can’t justify the expense otherwise. That will mean no bills for me. A ready made system will be the go I think. It was too hard trying to match all components and the more i looked into it the harder it looked.

Hi Jeff, I guess a complete stackable home ESS would be suitable for you. Easy to install and operate. 5.12kwh per module(51.2V100Ah), and 3 modules in a series connection will give you 15.36kwh.

Sounds like you’ve taken on quite a project – respect for diving into the DIY route!

Those 320AH batteries sound epic, but yeah, it can get tricky with all the inverter/chargers, BMS, and whatnot. There are a few DIY enthusiasts around here who might be able to help, but if you’re feeling overwhelmed, hiring an engineer could be a solid move to ensure everything’s safe and efficient.

If it feels too daunting, selling the batteries and rethinking might not be a bad idea either. Whatever you choose, props to you for taking on the challenge! Good luck!

The 16 EVE 280Ah LiFePO4 batteries arrived in 8 boxes over 5 days. Each cell was precisely 3.25 volts, making assembly straightforward. Polarity is marked as plus (BLACK) and minus (TAN). Secure mounting is required due to 8mm tapped pads and longer studs for 1/4 inch copper bus bars.

The cells were configured into 2 parallel 4s strings, each with 560Ah and equipped with 2 Qinizx 5 amp equalizers. OEM packing material and Velcro strips were used to secure and insulate the cells. After a 7-hour charge at 120 amps, the 12-volt string (1120Ah nominal) was tested at 13.15 volts (50% SOC) with an internal resistance of 0.7 milliohms. The voltage drop under a 125-amp load was minimal, less than 0.1 volts.

The batteries, maintained with a 13.1-volt float charger, have replaced 8 Trojan T105s and performed exceptionally well. Voltage drops to 12.94vdc at 40F, showing slight capacity loss. It’s advisable to heat the storage area to 50F and avoid charging when temperatures are below freezing.